Finishing – Chemical

"What type of finishing do I need for my aluminum extruded component?"

At Alexandria Industries, we understand the different finishing options and their potential impact on your product's surface.

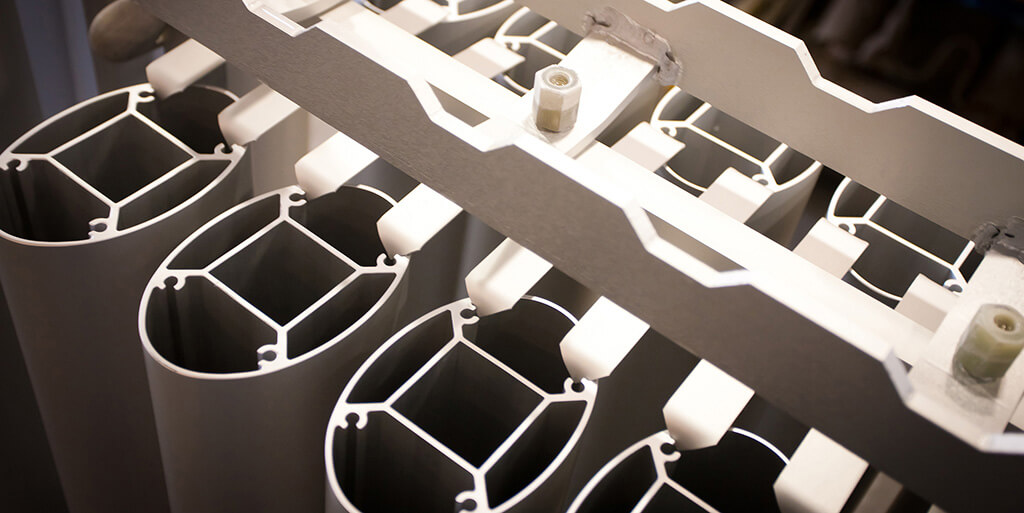

A finish can be as good (or bad) as the product's raw surface. Before we recommend anodizing, etching, painting or plating your product, we start with the finest aluminum and the best extrusion press practices in the industry. We maintain the tightest industry tolerances. We also maintain strict process, chemical and electrical control, to add the finishing touches to your components.

From anodizing to our unique ExtremEtch™ finish, we are here to help you select the best options for your metal finishing needs.

- Anodizing is one of the most common and durable chemical finishes.

- ExtremEtch produces an evenly distributed matte finish, without sacrificing the high tolerance features needed to meet your extrusion requirements.

- We offer two types of painting – liquid or powder coating – product finishes. Your final product needs determine the best coating option.

- Plating is another chemical finishing process that provides a surface covering to your components.

Our chemical finishing services can also help reduce your product quality issues by lowering opportunities for freight damage and costs that occur when shipping products between multiple suppliers.

We don't expect you to know the best finishing solution for your components. That is why we are here to help you choose from the many options we offer. Key to helping you decide which finish you need will depend on your product's end-use requirements.

Ready to Start a Project?

We can help you get started and determine what your product solution might look like.

Related Processes

Projects we've helped our customers create

Solutions

Simplifying your supply chain makes your job easier...

Why Alexandria Industries?

There is more to manufacturing than piece part price...