Woodworking toolmaker Kreg Tool builds supplier relationships that drive business

Anyone who has ever used a hand drill or framing nailer knows the satisfaction of having the right tool for the job. Leading woodworking toolmaker, Kreg Tool, based in Huxley, Iowa, knows what tools are right for the job because it knows what’s important to its customers, and what’s impeding their success. The company’s tools not only make difficult woodworking tasks simple, they inspire customers to make great wood products with exceptional skill.

The company’s success in developing the right tools for its customers relies on its success in developing the right relationships with its component suppliers.

Seeking suppliers that bring overall business value

Like many manufacturers, Kreg Tool works with a number of component suppliers that are essential to developing tools that meet its customers’ demands for product quality and ease of use. Determining which supplier is the right one for its business is a carefully thought-out process.

For example, at one time, Kreg Tool worked with three aluminum extruders to supply its components. One supplier consistently shipped components that arrived damaged and missed required quality tolerances. Another supplier, responsible for finishing the components, was unable to get the blue color of Kreg Tool’s brand to correct specification. With its brand image and business success so connected to its suppliers, Kreg Tool must strategically evaluate and cull its supplier list to include only those that have a proven record of delivering real business value.

Scott Lemon, purchasing manager at Kreg Tool, has spent nearly a decade managing supplier relationships. For Lemon, maintaining strong relationships requires purchasing savvy, along with logistical and financial finesse. Getting the best price is only one aspect of getting the best value. He believes that building solid relationships with suppliers can make a huge difference in getting product to market in a cost-efficient manner.

“If you’re looking to drive cost out of something, you’ll never build a partnership with your suppliers,” Lemon said. “To build a partnership means evaluating suppliers based on total-cost-of-purchasing criteria instead of just the cost of the parts. If I don’t get quality components delivered on time, cost doesn’t matter.”

Lemon seeks suppliers that bring manufacturing expertise with value-added services like engineering assistance, finishing, and assembly. He found such a partner in Alexandria Industries, a producer of engineered products that offers a vertically integrated supply-chain solution and adds value to its manufacturing processes by doing more of the work for its customers.

Build success with a business partner focused on what’s best for you

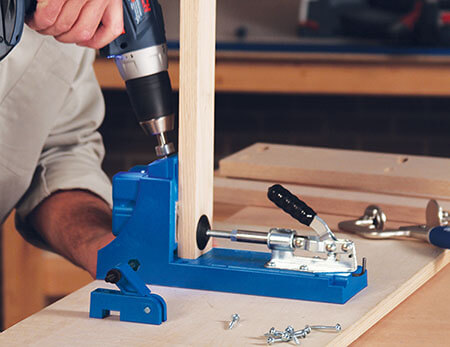

To meet the short lead-time demands of purchase-wary consumers during the Great Recession, Kreg Tool needed suppliers it could rely on to deliver parts quickly. Because he was experiencing unresolved quality issues with his other suppliers, Lemon worked with Alexandria Industries to manufacture an aluminum-extruded component for the company’s Rip-Cut™ tool. The Rip-Cut improves woodworkers’ accuracy and efficiency when cutting down large pieces of wood with a circular saw.

Engineering experts at Alexandria Industries worked closely with Lemon early in the design phase to help ensure they could make Kreg Tool’s components exactly to specification as well as provide value-added engineering assistance. By understanding Kreg Tool’s quick response needs and its commitment to extending customers a lifetime warranty on any manufacturing defects, Alexandria Industries’ engineers suggested switching the tool’s aluminum alloy from 6063 to the leaner 6060 alloy. The leaner alloy extrudes faster and offers the right properties needed for end-product usage. This change saved Kreg Tool both time and money without diluting its promise of quality.

Lemon then partnered with Alexandria Industries to extrude and anodize the block component for its Kreg Jig® – the product on which the company was created and the most popular tool. Anodizing the component with the right shade of Kreg Tool-blue consistently was challenging. Maintaining color density, other than silver or black, is extremely difficult because in dyeing anodized film there are more variables to control, such as solution composition, temperature and time. The more parameters to control, the more difficult it is to get the same appearance in metal finishing.

The Kreg Jig is anodized with Kreg Tool’s iconic blue color. Maintaining color density, other than silver or black, is extremely difficult because in dyeing anodized film there are more variables to control, such as solution composition, temperature and time. The more parameters to control, the more difficult it is to get the same appearance in metal finishing.

Alexandria Industries worked with Lemon to quickly find a solution. It purchased a spectrophotometer — an instrument for measuring the strengths of the light in different parts of a color spectrum – and used it to measure the acceptable range of blue. Since then, Kreg Tool has had zero anodizing defects.

“It’s one thing to not have the manufactured components live up to my expectations,” Lemon said. “But I refuse to work with any supplier who lacks quality, or one who scapegoats when things go wrong. If something is not right, Alexandria Industries takes ownership and fixes it right away. You can’t put a price on that kind of relationship.”

Building relationships for a lifetime

The best relationships are based on similar values. The open communication and pursuit of excellence exhibited by the Alexandria Industries’ team align perfectly with Kreg Tool’s values. Lemon expects his suppliers to display the highest level of integrity and professionalism, and he has rewarded the supplier with a 98 percent supplier scorecard ranking.

“The ability of Alexandria Industries to make a quality product and deliver it on time, every time, was unmatched by my other two suppliers,” Lemon said. “No matter how much time and effort we put into forecasting sales, there will always be times when sales exceed our supply. It’s a good problem to have, so we keep it top-of-mind that our customers are what make us successful and consistently meet their demands.”

The experience of Alexandria Industries’ staff, the quick turnaround and quality parts that met or exceeded expectations, and the staff’s commitment to Kreg Tool’s business success was a game-changer for Lemon. After carefully evaluating his other suppliers’ skills and abilities, he decided to move all of his extrusion manufacturing needs to Alexandria Industries, reducing his aluminum extruder supplier base from three to one.

By streamlining his manufacturing needs, Lemon has not only reduced his supplier base, he is saving time and money by using a single-source, vertically integrated supplier that extrudes, machines and anodizes. Since reducing its supplier base and working Alexandria Industries, Kreg Tool has cut its supplier lead-time by 40 to 50 percent.

Committed to future growth

Kreg Tool’s educational material, customer support and online community resources provide customers with everything they need for long-term success. The company is so confident in the quality of its tools, and its suppliers, that it offers customers a lifetime warranty on any manufacturing defects. By listening to what they need and want, Kreg Tool builds long-term relationships with its customers, generating a lifetime of loyal woodworkers.