High-Quality Components Made in America Just for You

We create personalized, American-made components to satisfy our clients’ every need.

“What if my manufacturing supplier suddenly closes shop?” Because of COVID-19, product manufacturers have quickly realized how the virus has exposed weak links in the global supply chain. During and after the virus has run its course, many of you will likely see suppliers who will not survive. (Unfortunately, some of our aluminum extrusion competitors are closing.) Being...

From Industrial Widgets to Hospital Goods: COVID-19 Forces Minnesota Factories to Pivot. Reporter Dee DePass shares stories about Minnesota manufacturers, including Alexandria Industries, in this article about how, Industrial factories statewide have shifted into hospital mode, saving jobs in the...

At Alexandria Industries, we look forward to learning about your product development needs, and determining efficient and cost-effective ways to help you get there. We also appreciate when customers and prospects are curious to learn about our manufacturing processes and capabilities, which is why we wanted to focus on spotlighting our services. What Can We Do? If you like a good...

OEMs are wise to consider their entire product development needs, including the manufacturing requirements, before deciding where to do the work—internally or externally. Whether you manufacture your product components in-house or you outsource to a manufacturing supplier, consider which option would have the biggest impact on your organization’s vision and goals. The following...

Meeting the need for automated machining of lineal aluminum extrusions. Many components we make for customers are machined and cut from long lineal aluminum extrusions. To decrease the need to use multiple machines and processes, while reducing the number of times a production worker handles a part, our team of engineers designed a new machine—an Automator. The machining...

We guarantee your manufactured component features will match your design print requirements to a T – said no one ever – at least before taking a close look at manufacturability. The accuracy of product design prints keep customer-supplier relationships in harmony. It allows suppliers to manufacturer components to the print’s specifications and reduces future interruptions and...

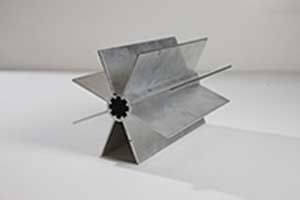

The first best step to ensure your aluminum extruded components are made to their design specifications, consistently, is to understand your extruder's tooling practices. Aluminum extrusion suppliers refer to the tooling used to make extrusions as “die tools.” Die tools include separate pieces that when assembled together are called a die stack. The product shape determines...

A product-manufacturing path seldom travels in a straight line. Instead, it can resemble our childhood games like Candy Land with a winding track or Chutes and Ladders with tracks all over the place. The path typically consists of more than one manufacturing process, with different tasks for each process. Individuals working in separate manufacturing areas performing different tasks...

Do you have a good sense of the overall value of your suppliers? Are they working to make a difference in your product development and speed to market? If the answer is no, you should find a new supplier. Alexandria Industries will always look at different ways to help customers adapt their product designs to the manufacturing process used to make them, while identifying and...

Development of new products can be the key to success for so many manufacturers. Here are five tips to help you successfully develop new aluminum extruded profiles for your products. Involve your extruder early in the process. First to market often wins. By getting your extruder involved early in the product design and development process, OEMs can reduce start-up costs, and...

2025 Alexandria Industries. All Rights Reserved.

© 2025 Alexandria Industries. 401 County Road 22 NW, Alexandria, MN 56308. All Rights Reserved.