5 Ways to Evaluate Aluminum Extrusion for Wider Application

The following article was published in Design News magazine (Jan. 27, 2015)

Since appearing on the automotive scene in 1899, aluminum has taken a somewhat leisurely route to establish itself as “the manufacturing material of the future.” Ford Motor Company kicked off the material’s belated coming-out party with production of its 2015 F150 truck body and bed components that are 97 percent aluminum alloys.

After more than a century of progressively more mainstream application of aluminum – enabled by continual processing, fabrication and alloys innovations – the material seems to have (finally) arrived.

Each aluminum alloy has different elements added and undergoes modified extrusion processes to achieve the specific goals of the extrusion.

But the aluminum contribution is not limited to design and engineering solutions for automotive lightweighting. Its popularity is increasing not only throughout the transportation sector, but also in construction, solar, medical, electronics, and other industrial applications.

The increasing prevalence of aluminum in thousands of everyday products validates the material as high-end horsepower that will drive historic shifts in how steel-deploying manufacturers design, develop, fabricate, and integrate components or assemblies. This is especially true within the context of slimmer production budgets, tighter production schedules, supply chain complexity, and consistently more rigorous competition.

But advances in aluminum-based product design and engineering are not ramping upward based only on its alloys. There is a parallel story in how the methods for designing and manufacturing with aluminum have evolved. The story is filled with lessons manufacturers have learned – and techniques they have perfected – when it comes to manipulating aluminum for steadily broader application.

With aluminum on an industrial upswing, now is the time to evaluate extrusion as the material’s “force multiplier.” In this context, extrusion is a production technique and technology that, when combined with aluminum’s growing acceptance, can catalyze innovation even faster and more broadly across product R&D and manufacturing.

The constantly accelerating innovation pace in the auto industry is a good indicator that aluminum isn’t simply for stamped structural applications motivated by lightweighting. The Aluminum Extrusion Council (AEC) estimates the 2015 Ford F150 includes more than 40 pounds of extruded components. And, an AEC-sponsored report forecasts that the average per-vehicle weight of shapes extruded in aluminum, across all vehicles, will nearly triple over the next 10 years, indicating the material’s growth.

Elsewhere in the transportation sector, trailer manufacturing previously required bending, fabricating and welding sheet metal. Today, OEMs use lighter, one-piece extrusions for trailer frames and components that enable slide-together assembly. Similarly, solar manufacturers continue to refine the durability of aluminum-extruded racking and mounting systems by leveraging the versatility to add material and concentrate strength or durability precisely where required.

OEMs who seek guidance from aluminum extruders early in the design stage can benefit from selecting the best alloy, surface finish and specialty features to achieve their product development goals.

The development-to-delivery focus for every manufacturer is, “What’s possible next?” Media coverage anticipating the new Ford F150 rightly credits the aluminum surge as a revolutionary development for the automotive industry. Superlatives used to describe how aluminum will impact the future of auto manufacturing consistently support the material’s “game changer” status.For medical equipment OEMs, rigorous material performance standards in medical applications make stainless steel the traditional specification to meet sanitary use and maintenance requirements. Yet with proper finishing treatments – including artificial aging and anodizing – extruded aluminum can be less porous and cleaner than stainless steel. The inert chemical compounds in aluminum, combined with proper finishing techniques to help prevent corrosion and chemical absorption, are critical to contamination prevention in medical care applications.

The story arc for extrusion includes similarities to aluminum’s automotive emergence. Extruded aluminum has steadily gained ground as relevant and strategic in every manufacturing aspect, especially product development and supply chain optimization. But the process has progressed relatively quietly.

Aluminum extrusion’s old-school heritage – other than wartime applications at the beginning of the 20th century – was not heavily industrial. Today, extruded aluminum components and assemblies are strategic factors in industrial manufacturing, with a key role in enabling OEMs to lower product lifecycle costs while making step-function improvements in product design, engineering and performance.

But manufacturers – influenced by understandable biases toward more familiar materials and processes – tend to experience only a small amount of what extrusion makes possible.

This Is Not Your Father’s Aluminum Extrusion

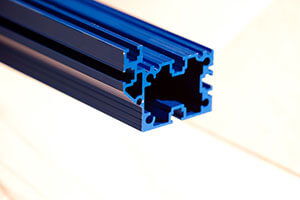

The point where aluminum properties intersect with extrusion is manufacturing industry proof that the whole is greater than the sum of its parts. There is a “perfect storm” where lightweight, high-strength aluminum meets the design and engineering versatility that extrusion enables.

Different aluminum alloy properties offer different benefits. The 6000-series alloys, for example, ease extrusion and offer bending and forming flexibility, along with high strength-to-weight ratios. Combining the ability of concentrating strength where needed – plus using heat treatment to artificially age and harden the aluminum following extrusion – drives a part production process that is less expensive and cycles faster than traditional machining. A manufacturer can extrude precision-engineered, high-tolerance aluminum lengths of 125 feet in minutes, cut it quickly, and artificially age it over a few hours.

Extruded components designed with screw bosses, hinges and many other features, allows them to incorporate easily with mating components. The metal alloy’s properties, combined with surface finishing, offers easy-to-care-for finishes and non-corrosive material properties, giving designers the wear resistance and reliability they need.

Consider the potential for innovation where appropriately alloyed and treated high-tensile aluminum connects with extrusion to form complex, near-limitless shapes and profiles that can reduce (or eliminate) machining, joining, fabrication and assembly operations, along with shipping and handling required for multiple processes from multiple vendors. And that is before factoring in short lead times for extrusion tooling or less expensive tool costs – particularly for achieving close tolerances – compared to alternatives like machining, die casting, roll forming and metal stamping.Extrusion dies, meanwhile, open the door to virtually unlimited design versatility and enhanced manufacturability. The ability to easily integrate design features reduces secondary processing like machining and welding, drives down material cost and reduces part counts. Die design versatility includes incorporating lap joints, dovetails or hinges to streamline assembly when mating with other components. Extruded components can also use T-slots for adjoining bolts to reduce or eliminate machining or welding.

Today’s inventory of extruded aluminum characteristics tracks very favorably with an R&D wish list for materials and processes that add value in areas like design versatility, streamlined product development, manufacturability, cost-to-produce, cost-to-assemble and performance. As a result, using a “total cost to produce” analysis and validation, even the higher material cost of the alloy compared to steel increasingly falls away as an obstacle to designing with or transitioning to aluminum.

| Weight | Aluminum is about 1/3 the weight of iron, steel, copper or brass, making aluminum extrusions easier to handle, less expensive to ship, and relevant for applications where weight reduction is a priority. |

| Strength | Aluminum extrusions can be made as strong as necessary for most applications. Extrusion can concentrate strength where it’s most needed by varying wall thickness and including internal reinforcement in the profile design. |

| Strength-to-Weight | The unique combination of high strength and low weight makes an aluminum extrusion ideal for applications where load-carrying is a key performance indicator. |

| Seamless Constructs | Extrusion can achieve complex shapes in one-piece sections without relying on mechanical joining. The resultant profile is typically stronger than a comparable assembly, and less likely to break, loosen or leak over time. |

| Customization | The ability to design a profile to meet specific functional, aesthetic and manufacturability objectives makes extruded aluminum a preferred element in product solutions. |

| Time-to-Market | Aluminum extrusion tooling is relatively inexpensive and involves generally shorter lead times, which facilitates faster prototype development, testing and product launch. |

| Fabrication and Assembly | Effective aluminum extrusion design can greatly simplify subsequent fabrication and assembly. Producing extrusion-based components and assemblies routinely employs a wide variety of fabrication processes. |

| Corrosion Resistance | Aluminum extrusions offer excellent corrosion resistance; they do not rust. A naturally occurring oxide film protects the aluminum surface. Anodizing and other finishing processes can enhance protection. |

Fig. 1: Examples of aluminum extrusion characteristics that add value in product development. (Aluminum Extruders Council, www.aec.org) |

|

How to Evaluate Extrusion Fit

Maintaining creative energy and forward momentum is critical for every manufacturer. Innovate out of necessity. Innovate by exploiting a specific opportunity. Take the risks inherent in breaking new ground.

Without routinely doing some or all of the above, the year-over-year productivity gains manufacturers grind out in percentage fractions are unlikely -- and probably impossible. Most important, if productivity lags, underperformance on profitability and competitiveness follows. That’s especially true within segments or markets where forward-looking competitors set the pace.

But R&D-stage resources have limits. And supply chains already have too many moving parts. Given those realities, supply chain collaboration, efficiency and value creation are critical. It is essential to put an OEM’s product expertise and a supplier’s specialization together for the specific purpose of moving beyond incremental change and taking outcomes to the next level.

Is aluminum extrusion that kind of opportunity? It’s probably more relevant than previously perceived, especially if OEM product development functions have yet to focus on the option. But extruded aluminum is becoming more relevant all the time. Ford ultimately justified and produced a 97-percent aluminum truck body and bed.

The same is true for supply chains that are incorporating extruded aluminum components in certain scenarios but have not transferred the approach to other projects. The reason? Material and process biases are real; they come from previous knowledge, experiences and solutions that have worked to this point.

At the same time, there is the saying, “if all you have is a hammer, everything tends to look like a nail.” What will it take to make the shift?

Here are five questions – filters based on key design, production and performance variables – product development teams can apply to determine whether there is reason to start – or move deeper into – aluminum extrusion adoption:

1. Is aluminum really strong enough? How does the high strength-to-weight ratio come into play?

Driven by manufacturers desiring to push the envelope on aluminum use, material suppliers are working aggressively to develop alloys that significantly narrow the difference with other materials in strength properties. The alloys advancements also upgrade properties-driven performance in areas like machinability, formability, hardness and wear resistance.

Equally important, aluminum extrusion can put metal where component function and performance require it most. Extruding a critical feature like a web, for example, can reinforce a square aluminum tube. Putting metal where it’s needed – and avoiding profile density when strength is non-critical – can reduce weight by one-half to two-thirds, depending on how much aluminum is required.

The buzz around the Ford F150 comes from success in using aluminum to make the truck as much as 700 pounds lighter than previous -generation models. The improvement, as Popular Mechanics described it, equates to removing the entire engine – without comprising strength and safety. Not every fabrication project scales to that level of strength-to-weight. But when properly done, aluminum extrusion has the capacity to achieve the same outcome in a broad range of applications.

2. How much upside can extrusion-driven design flexibility and customization create?

An industry rule of thumb says that 70 to 80% of a product’s cost is determined at design completion. Experience also indicates that a manufacturer commits to 60% of cumulative lifetime cost even earlier, at the concept stage.

The permanent pressure of cost reduction alone justifies the high frequency of incoming prints that result in some degree of supplier redesign. If an OEM aspires to the philosophy that everything can be made better, it’s understandable and expected that design improvement happens regularly in the hands of a supplier that sees the big picture using a specialized perspective.

All of this makes design improvement an automatic, across-the-board opportunity within the supply chain. The variable that distinguishes one supplier from another, or one production process from the next, is how much an OEM can move the needle. How high is the upper limit on making something smaller, lighter or faster? What is possible in terms of reducing material handling and processing or eliminating secondary manufacturing processes?

The potential in combining multi-benefit extrusion with “the material of the future” should lead to higher expectations for what is possible across the component manufacturing space.

As an example, the extrusion process’ ability to add or take out profile features – in order to optimize weight-to-strength – lets the OEM take a custom approach to design, rather than being constrained by off-the-shelf material stock. The potential increases further when product R&D includes early, upstream OEM and supplier collaboration on what extruded aluminum can accomplish.

3. Does corrosion complicate developing a complete, single-source solution?

Longevity and durability play a critical role in functional performance. Appearance matters when the application includes an aesthetic objective like the mirror finish on a medical device. Any susceptibility to corrosion undercuts longevity, durability and appearance performance.

Aluminum is the most corrosion resistant of the metals commonly used in manufacturing. The substrate’s naturally occurring oxide film creates surface protection that turns away the threat from outdoor elements, corrosive environmental conditions, or exposure to materials with corrosive properties. Anodizing and other finishing processes can enhance protection further.

Bridges, semitrailers, docks, large shipping vessels – and now a Navy carrier constructed using a significant amount of aluminum – are corrosion-resistant application examples from a heavy industry perspective. Examples of “severe-duty” consumer market applications include solar energy structures and an increasing array of medical technology innovations. Across the board, there are fabrication challenges manufacturers can meet much more effectively by using extruded aluminum to integrate anti-corrosion protection with lighter structures, produce parts with equal or greater strength than traditional ones, and design versatility.

4. Is there room in the supply chain to shorten ‘time-to-market’ delivery?

There is unlimited information on supply chain best practices for optimizing industrial manufacturing that turns “possibility into product” as fast and efficiently as possible. In a perfect world, the objective is to reduce lead times while simultaneously delivering quality that helps an OEM differentiate itself in the marketplace.

At today’s pace, and in the context of what it takes to compete on new products, the real question for suppliers and OEMs is whether achieving only incremental change will be sufficient. Most likely, it is not. “Steady improvement” will compete less successfully with a supply source – and a manufacturing process.

The nature of aluminum extrusion, in general, and in comparison to other methodologies, offers a dramatically faster turnaround for R&D-stage projects. That’s especially true if the OEM brings extruded aluminum expertise into the product development process early. Under that scenario, it may be realistic to expect extrusion dies and prototype parts as rapidly as two weeks from request.

Equally critical, the R&D process utilizes components that reflect an actual production state instead of working with lesser parts that represent a “dumbing down” prototype phase.

5. Can any other metal make the sustainability contribution?

A discussion on the key advantages of extruded aluminum is incomplete without noting the process not only can deliver highly complex, tight-tolerance and light-but-strong components but also does so while utilizing the only material that can be recycled indefinitely without losing any of its properties.

Taken to the extreme – and putting the sustainability impact in manufacturing context – no extruded aluminum component should ever end up in a landfill.

Bullish on Innovation’ Is ‘Bullish on Aluminum Extrusion’

Highly regarded author, research scientist and global trends analyst Vaclav Smil believes the demise of U.S. manufacturing would also mean the end of creativity. As he told Wired magazine: “Innovation is tied to the process of making things.” In other words, the manufacturing sector is the most important and productive creativity engine.

Most innovation, Smil said, results from a company’s desire to extend product reach, improve costs, or increase returns. Well in advance of the new Ford F150’s unveiling, he pointed out: “Innovation usually arises from somebody taking a product already in production and making it better. Innovation always starts with a product.”

In the same interview, Smil referenced “better aluminum” as an example of innovation that product-inspired, manufacturing-driven creativity can generate. That is why extrusion technology is uniquely important as aluminum’s force multiplier. It is a production technique that can make the second most-used metal into an industry game-changer, from product R&D through manufacturing.

The breakthrough composition of a consumer truck body may have spiked more juice and interest around what aluminum makes possible. But the newly energized R&D thinking and creative problem-solving that’s on display isn’t limited to the material that enables making lighter planes, trains and automobiles.

Smil likely would approve of any manufacturer that combines innovation-driven aluminum and extrusion as a unique opportunity to spark big, creative leaps forward.

Sidebar: Aluminum Extrusion for Precision Medical Equipment

Sunnyvale, Calif.-based Accuray relies on its component suppliers to help design, develop, and integrate components to bring to market leading equipment, such as its TomoTherapy System.

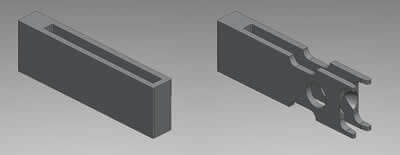

The TomoTherapy oncology radiation system involves complex computing and hundreds of mechanical parts to precisely apply an individualized radiation treatment. Shortcomings with couplings for an internal electro/pneumatic/mechanical assembly threatened the machine’s uptime.

Accuray sought to improve the performance reliability and cost of components machined from steel stock using electrical discharge machining (EDM). The process required several manufacturing steps and came with a high part price. In addition to avoiding coupling failure, the medical equipment maker wanted to reduce full-assembly part count, part cost, and cost to assemble.

An aluminum extrusion solution identified slight design variations from the original drawing that would improve the part’s overall strength and durability, and assure repeatability from the tooling. Following the component extrusion, the process included machining and anodizing surfaces to the specified hard-coat thickness tolerance to increase wear resistance and simplify mating assembly for its intended snap-fit design.

|

Enhancing the mechanical properties to prevent breakage, the couplings were manufactured using aluminum extrusion, machining and hard-coat anodizing, increasing wear resistance and simplifying mating assembly for an intended snap-fit design. |

To lower the total part count and assembly labor cost, Accuray’s senior sustaining engineer, Bradley Brunker, designed the extruded coupling to snap-fit to its mating components. The design solution cut assembly labor by 30 to 60 minutes for each completed assembly. Using an aluminum-extruded part also cut component-manufacturing costs by nearly 90 percent and took only a quarter of the time to produce. And because of the couplings’ snap-fit geometry, the OEM also eliminated a tool previously used for assembly.

Rodney Floding is Alexandria Industries' QROC Supervisor, overseeing customer service, estimating and drafting and tying the company’s sales and service groups together. Previously serving as the company’s die design/extrusion engineer, Floding brings a solid skill set of seeing the big picture for customer orders, applying his technical expertise and engaging with customers early in the product design and development. He can be reached at 320-762-7644 or rfloding@alexandriaindustries.com.